Automatic air feeder machine for power press

automatic air feeder machine for power press,After-sales Service Provided:

Engineers available to service machinery overseas,Local Service Location:

Egypt, United Kingdom, Viet Nam, Brazil, Indonesia, Malaysia$1,000.00 – $100,000.00/ set|2 set/sets(Min. Order)

- Marketing Type:New Product 2021

- Origin:China(mainland)

- Weight:as model

- Motor Power (kW):0.1kw

- CNC or Not:

- Normal

- Condition:

- New

- Machine Type:

- FEEDER

- Slide Stroke (mm):

- 20

- Power Source:

- Hydraulic, Hydraulic

- Place of Origin:

- Shandong, China

- Voltage:

- 380v

- Dimension(L*W*H):

- as model

- Motor Power (kW):

- 0.1kw

- Model Number:

- AFC

- Weight (T):

- 0.01

- Key Selling Points:

- Competitive Price

- Warranty:

- all life,one year for free, all life,1 years free

- Applicable Industries:

- Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Retail, Food Shop, Construction works , Food & Beverage Shops

- Showroom Location:

- None

- Marketing Type:

- New Product 2021

- Machinery Test Report:

- Provided

- Video outgoing-inspection:

- Provided

- Warranty of core components:

- 2 years

- Core Components:

- Bearing, Pump, Gear, Motor, Gearbox, PLC, Pressure vessel

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Color:

- The color can be customized

- Automatic:

- automatic

- Origin:

- China(mainland)

- Material processing:

- aluminum,carbon steel,stainless steel

- Weight:

- as model

- Power:

- as model

- After Warranty Service:

- Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

- Egypt, United Kingdom, Viet Nam, Brazil, Indonesia, Malaysia, Argentina, Colombia, Sri Lanka, Ukraine

- Certification:

- CE

- Supply Ability

- 100 Set/Sets per Month fully automatic punch press machines automatic air feeder

- Packaging Details

- Port

- Lead Time:

-

Quantity(sets) 1 - 1 >1 Est. Time(days) 10 To be negotiated

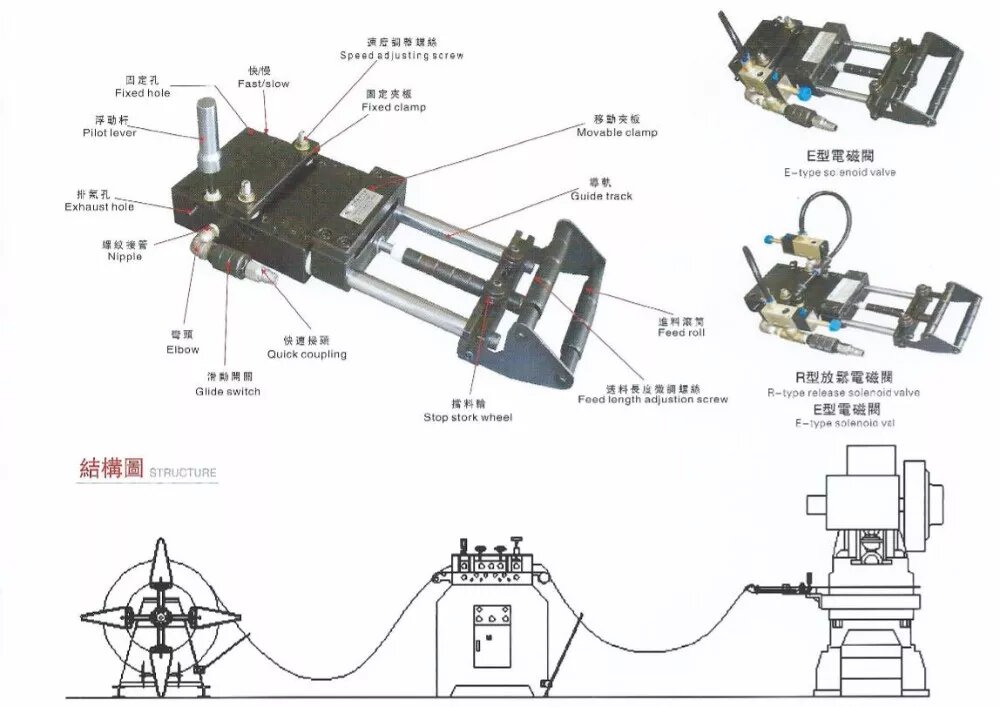

1. Type of feeder: Standard type, E-type, Standard & R type; E & R type

2. Applicable feeding material: metal strip, tape, plastic strip

3. A buffer is equipped on the models over AF-3C.

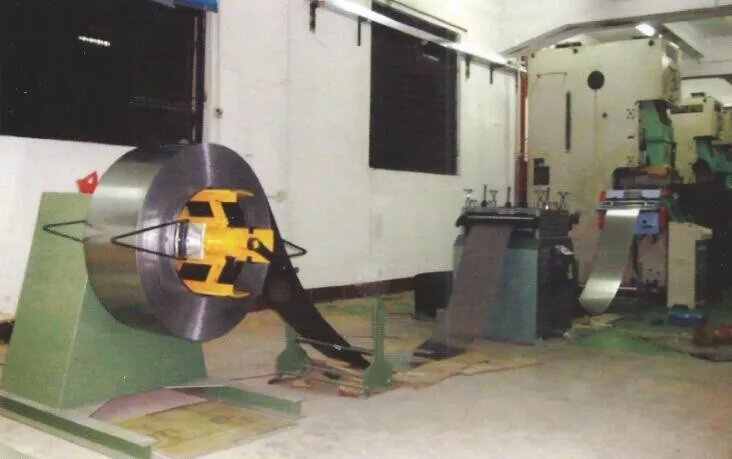

Air feeders, as a kind of automatic feeding device, are driven with compressed air. They are widely applied for press, press machine or punch, and it‘s for all industrial production.

Except the Standard type, other variations are all available upon request. E-type air feeder (instead of pilot lever, fixed with a pilot electromagnetic valve), Standard & R type air feeder (Based on standard type, added with an electromagnetic valve to make the fixed clamp carry a releasing function ) and E & R type (Both electromagnetic pilot valve and releasing valves are fixed ) can be supplied according to the real applications to different press machines.

If a high precision feeding is needed, an electromagnetic valve for the fixed clamp’s releasing function is required; if a shorter stroke or long distance feed is happened to the press process, an electromagnetic pilot valve must be fixed.

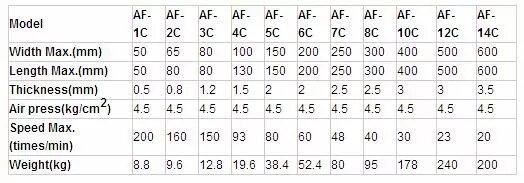

Technical Specifications

1. C-frame Power Presses With High Performance (25 ton to 800 ton)

1. Our manual uncoiler is suitable for coiling and uncoiling metal sheet or non-metal materials

2. Equipped with Japan magnetic contactor and electronic components, minimum breakdown and long operating life

3. Special design and equipped with heavy-duty roll bearings for best durability

4. Efficient automatic material feeding equipment, economy and practically

5. Can be provided with optional single speed or variable speed driving motoR Machine Alteration(Option) 1. Speed of feed 2. Material. I. D. 3. Material weight 4. Optional accessories for coiling thick sheets 5. Hydraulic expansion or air expansion

6. Variable speed driving motor or invertor control

7. Can be modified to meet your special requirements

8. Roller straightener and feeder in a same machine, achieve high precision required, reduce errors between the feeder and straightener.

9. Uncoiler and straightener combination can reduce the time difference between feeding and leveling and also save space.

Our manual uncoiler is suitable for coiling and uncoiling metal sheet or non-metal materials

2.Automatic Uncoiler (100mm to 3200mm)

1. Our manual uncoiler is suitable for coiling and uncoiling metal sheet or non-metal materials

2. Equipped with Japan magnetic contactor and electronic components, minimum breakdown and long operating life

3. Special design and equipped with heavy-duty roll bearings for best durability

4. Efficient automatic material feeding equipment, economy and practically

5. Can be provided with optional single speed or variable speed driving motoR Machine Alteration(Option) 1. Speed of feed 2. Material. I. D. 3. Material weight 4. Optional accessories for coiling thick sheets 5. Hydraulic expansion or air expansion

6. Variable speed driving motor or invertor control

7. Can be modified to meet your special requirements

8. Roller straightener and feeder in a same machine, achieve high precision required, reduce errors between the feeder and straightener.

9. Uncoiler and straightener combination can reduce the time difference between feeding and leveling and also save space.

3.Plate straightening machine (100mm-3200)

1. The leveler is suitable for straighten different metal sheets.

2. Equipped with Japan magnetic contactor and electronic components, minimum breakdown.

3. Hard-chrome-plated Roller, low wear, long operation life.

4. Head Coil Cradle. (TCD-type)

5. Efficient automatic material feeding equipment a dramatic increase in productivity is achieved by lane up with Auto Reel(TC-type).

4.Automatic Feeder (200mm to 3200mm)

1.The feeder employs a high performance NC controller for user friendly operation, high efficiency and simple maintenance.

2. Adoptd the high precision servo motor drive for convenient and fast operations. It saves preparation time and upgrades productivity.

3. The machine was developed by the extensive experience, which is ideal for long term operation, long service life, high accuracy and convenient maintenance.

4. Hard chrome plated rollers, low wear and high precision

1.Free installation, trial start and adjustment, training. But the machine quotation does not include the cha rges of our engineers in the buyer’s country if you want, and the buyer must take charge of all the expen diture including airplane tickets of our engineers when in the buyer’s country to do the service!

2.Warranty period is1 years. During the warranty period we shall reply to the call or Fax from the user for the

machine faults (expect for faults caused by no abiding by the relevant operation regulations, or by for ce injury) within 24 hours.

Question1:What is your minimum order ?

Answer: 1 Set.

Question2:What is your payment?

Answer: 30% T/T down payment,70% T/T balance before the delivery.

Contact Us For A Quick Quote

Full Automatic air feeder machine for power press

Support

Design Support

Email Support

Towable air compressor Solutions

Local Team Support on Automatic air feeder machine for power press

Automatic air feeder machine for power press

from Manufacturers in China

Automatic air feeder machine for power press structure of a unique design, a compact, stylish appearance, high efficiency, small energy consumption, low noise characteristics and long life, is a smart environment-friendly products. Widely applied in metallurgy, machinery, chemicals, and mining, and electric power industries of the ideal gas source equipment.

If you are looking for a manufacturer of Automatic air feeder machine for power press in China, you are in the right place. Shandong Zollant machinery manufacturing Co., Ltd. is one of the most professional manufacturers and suppliers of Automatic air feeder machine for power press.